GalvCon

Our

software

is moving.

Optimized control software for surface finishing.

Classic

user interface

Unclear tables, hidden functions make the workflow difficult.

UTIKAL

user interface

Easy-to-understand symbols and clear structures ensure a high level of user-friendliness.

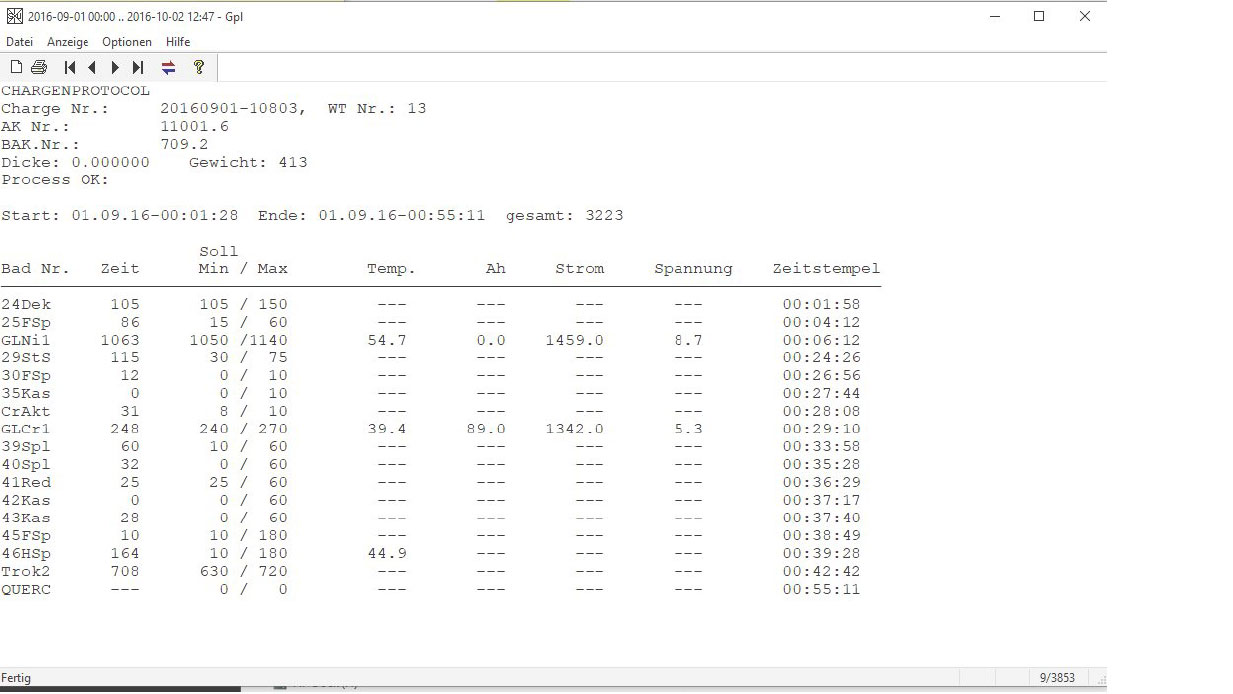

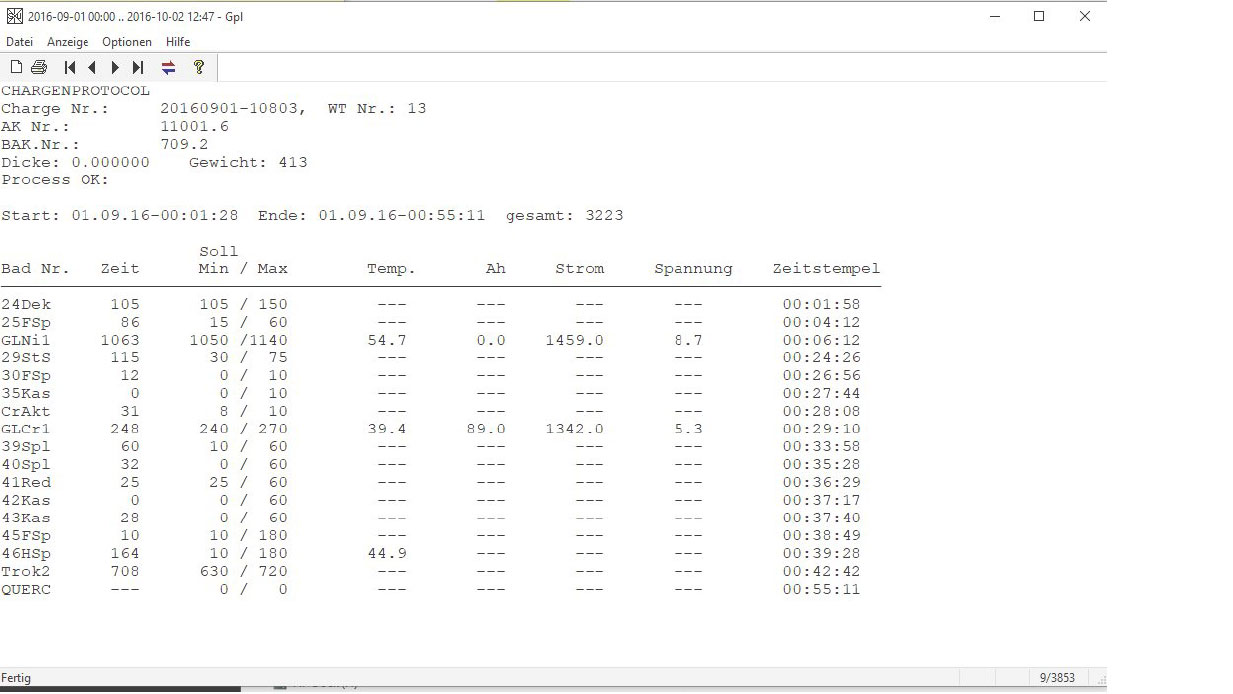

Classic

user interface

Unclear tables, hidden functions make the workflow difficult.

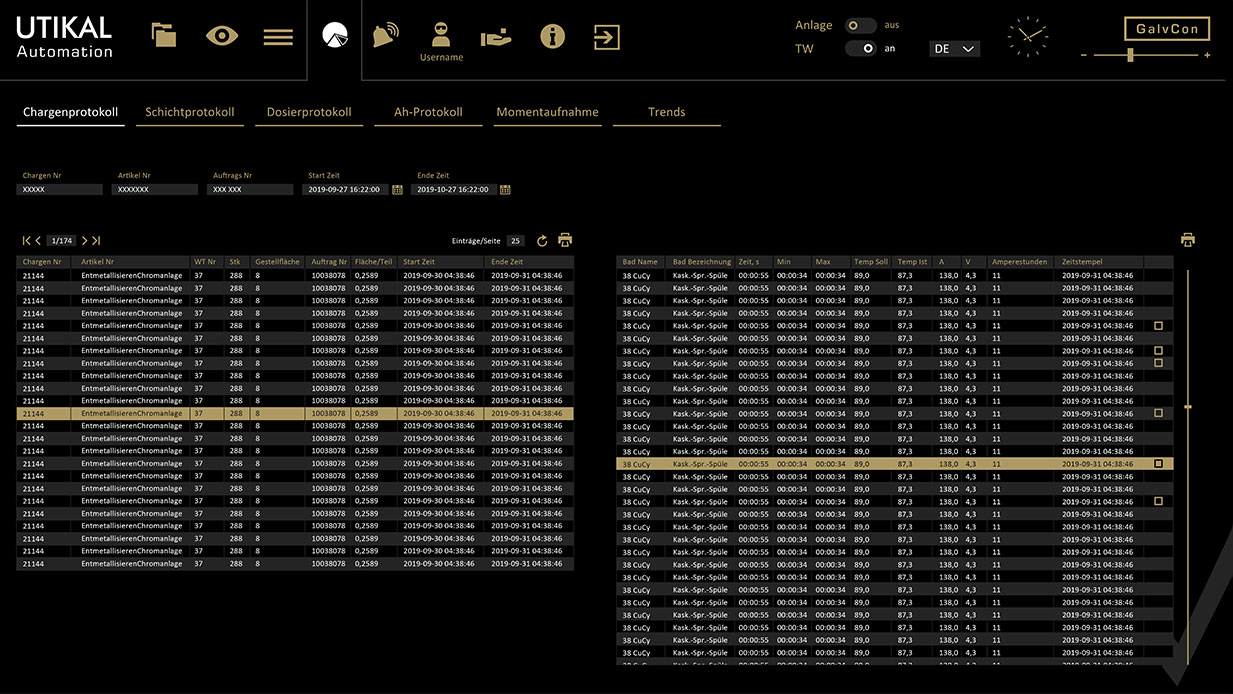

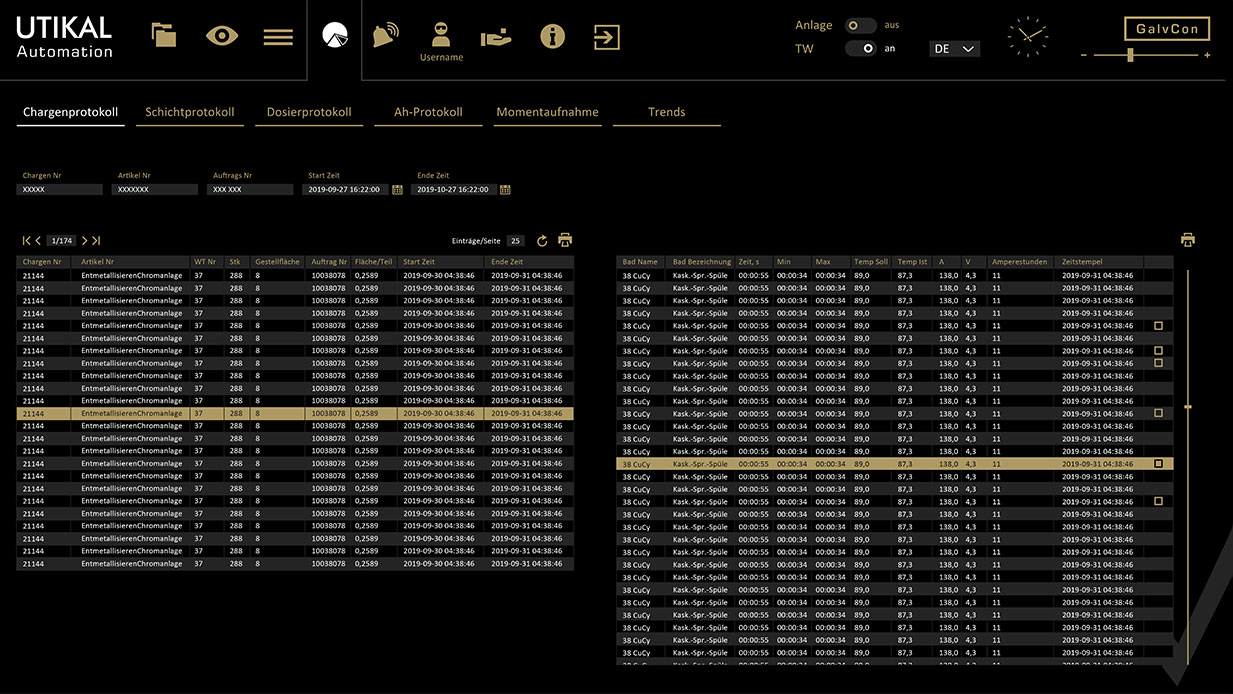

UTIKAL

user interface

Easy-to-understand symbols and clear structures ensure a high level of user-friendliness.

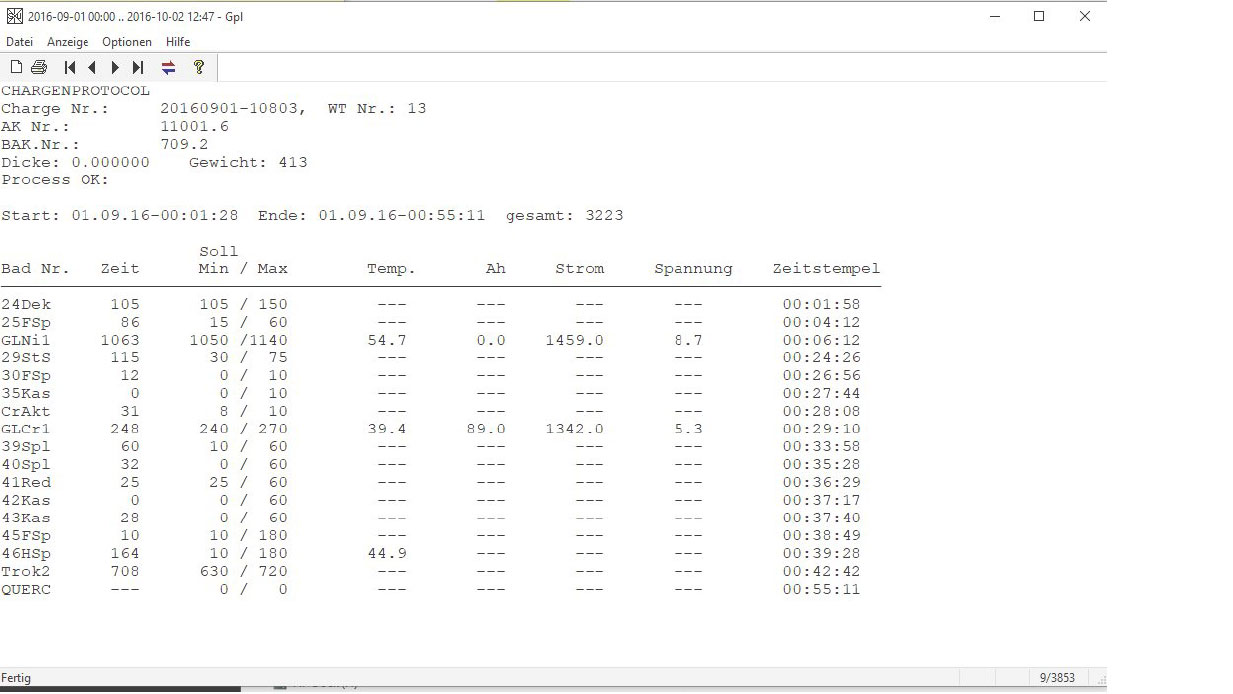

Classic

user interface

Unclear tables, hidden functions make the workflow difficult.

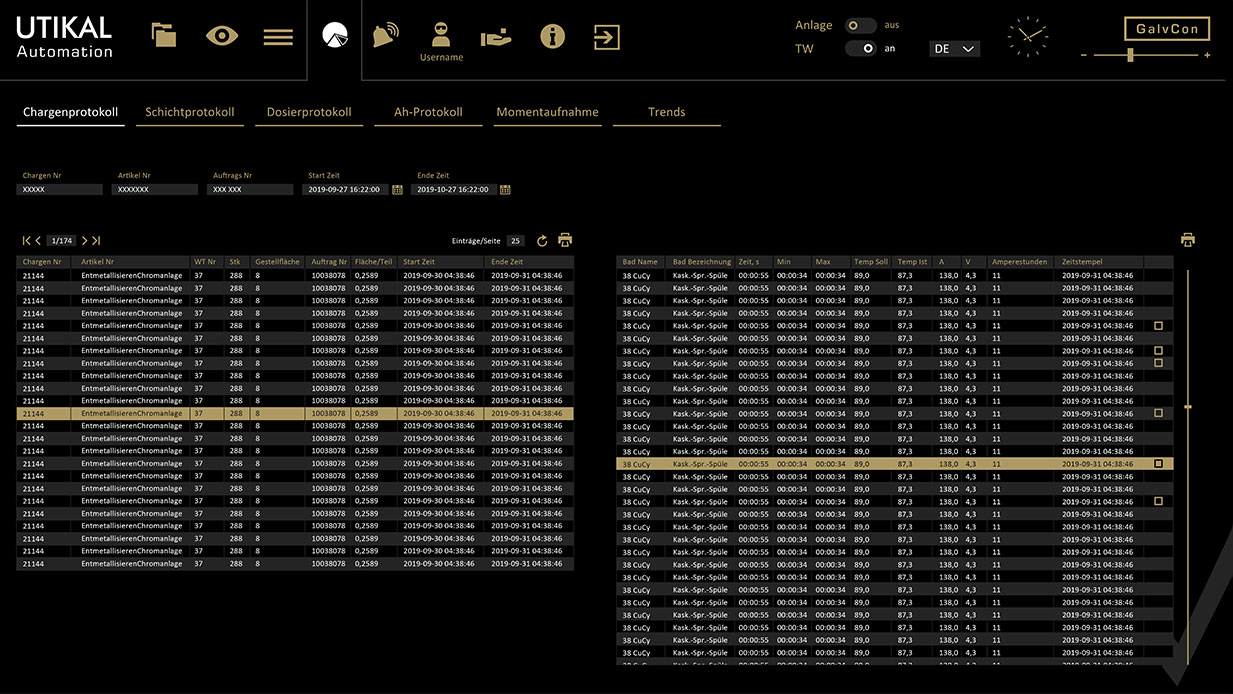

UTIKAL

user interface

Easy-to-understand symbols and clear structures ensure a high level of user-friendliness.

FUNCTIONS

Always, everything on sight.

Individual view

Components such as temperatures, rectifiers, metering pumps, various switches and other details are called up and displayed separately as required.

Reliably reports what your plant is doing.

The relevant charges with times, currents, temperatures, etc. per bath are carefully logged.

Production data can be requested and the plant capacity can be determined exactly.

See, how your plant performs in real time.

Our graphical 3D plant overview shows you your plant in real time. The baths are visualized to true scale on the screen. The racks or the drums are shown both when moving on the transport trolley and in the baths.

You can follow the movement of the transport trolleys and view the details of the baths.

You determine how your plant behaves.

Your plant is controlled according to article numbers. You determine the process program with your input. You define the bath-specific values such as dripping times, currents, temperatures, etc. and specify the batch sequences to be run. The operator enters the article number and the system automatically retrieves the surface treatment parameters and starts the sequence.

The GalvCon takes over the control of the transport trolleys, rectifiers, dosing pumps, temperature control, timers and many other devices.

Additional modules

Our

Plug-ins

The guard dog of your plant.

This module is for the maintenance of the equipment located in a surface coating or waste water plant. The baths and the tanks located in the plant are monitored and maintained.

We simulate superficially.

This module is used to simulate surface treatment plants, such as electroplating plants, hot-dip galvanizing plants, pickling plants and printed circuit board production.