AraCon

OUR

SOFTWARE

RUNS.

The optimized software for all industrial plants for wastewater treatment.

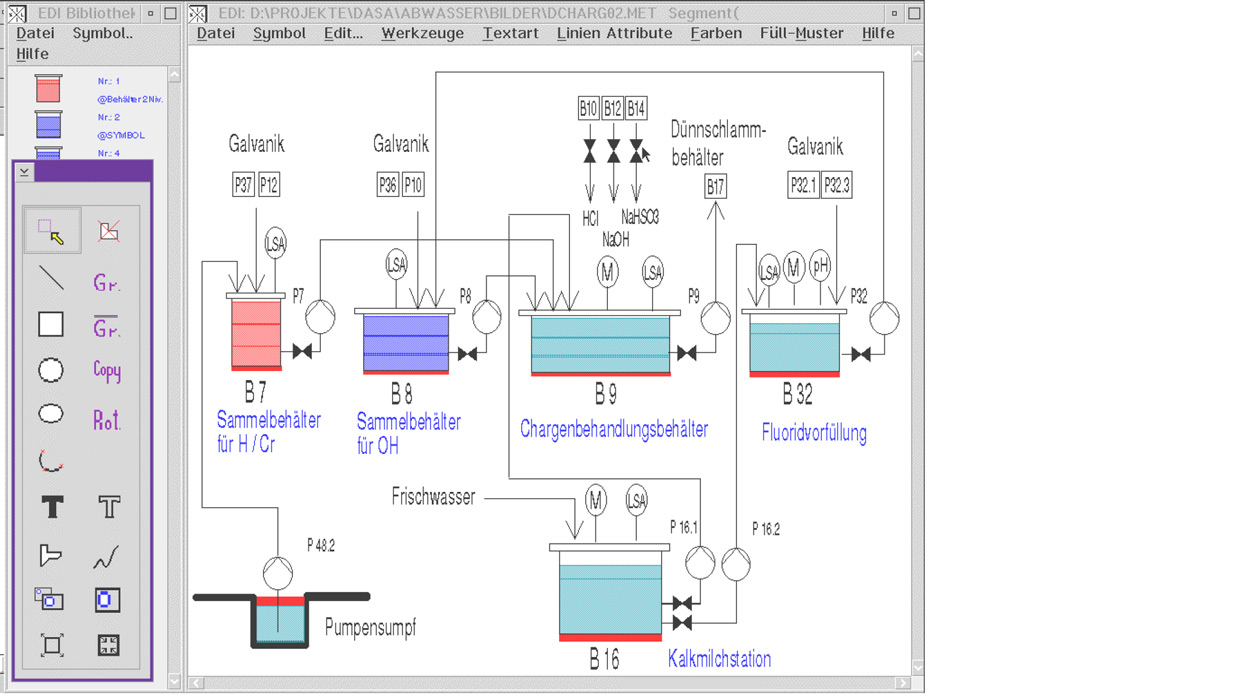

Classic

user interface

Unclear tables and hard-to-find functions complicate work unnecessarily.

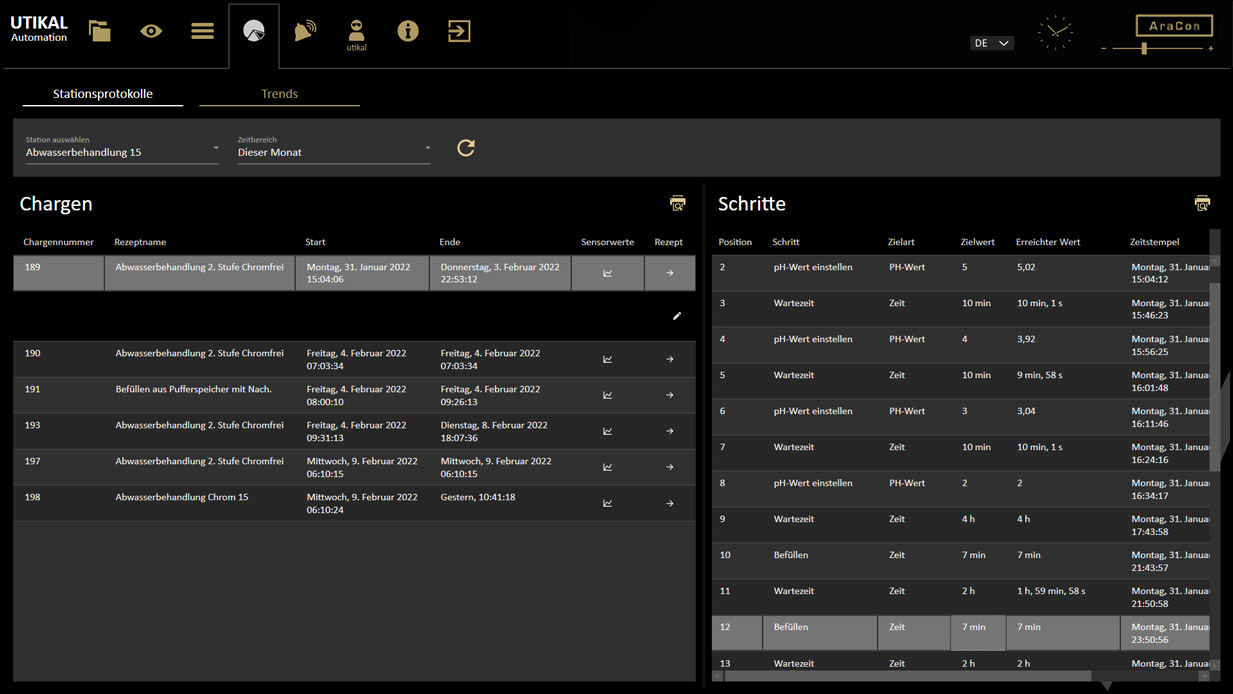

Our

optimized look

Our re-designed software does not only look good, but is also intuitive to use and learn.

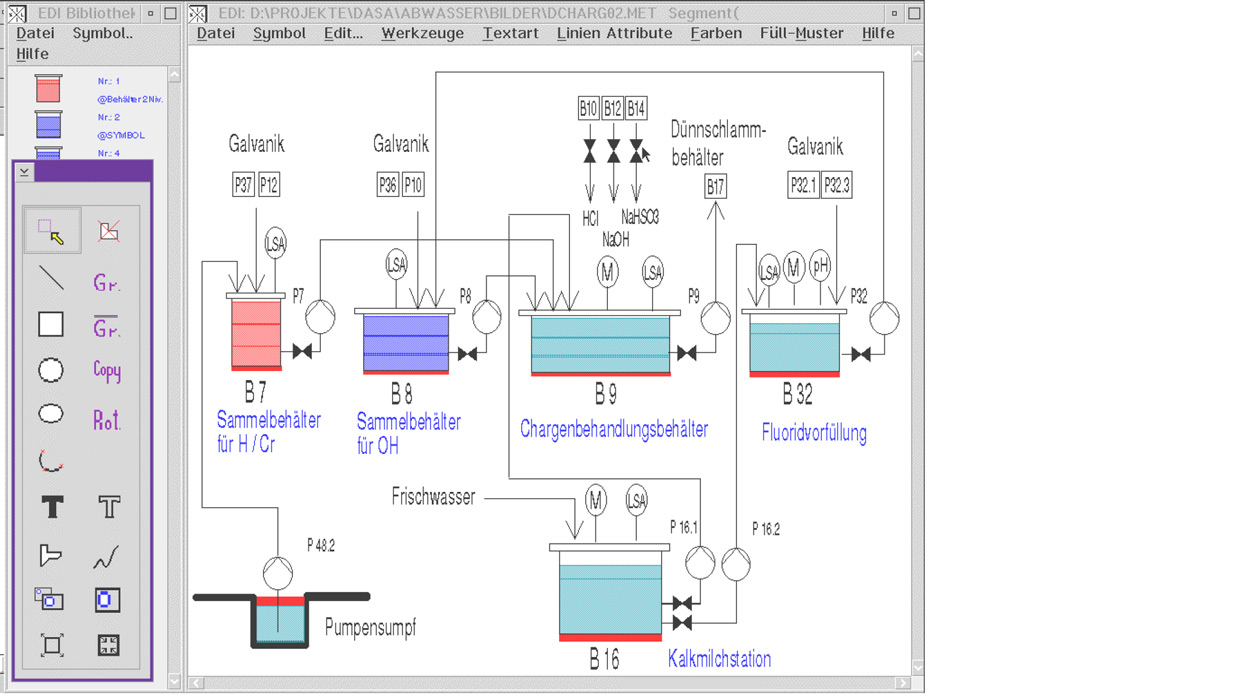

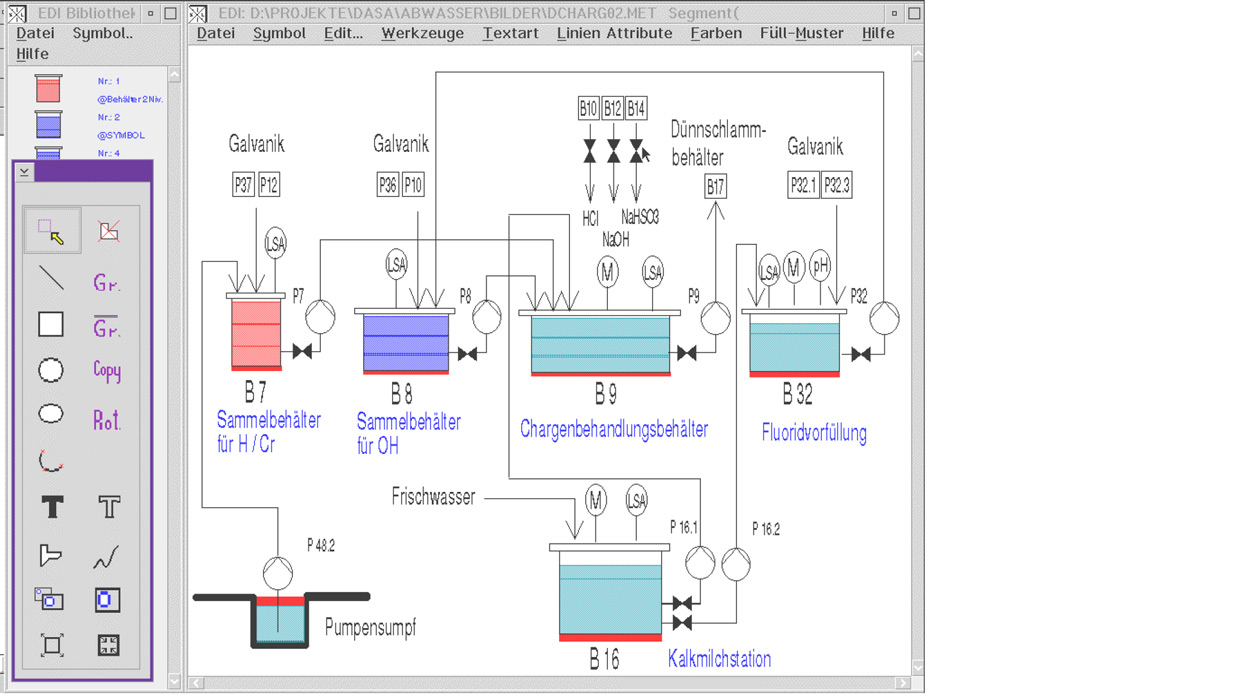

Classic

user interface

Unclear tables and hard-to-find functions complicate work unnecessarily.

Our

optimized look

Our re-designed software does not only look good, but is also intuitive to use and learn.

Classic

user interface

Unclear tables and hard-to-find functions complicate work unnecessarily.

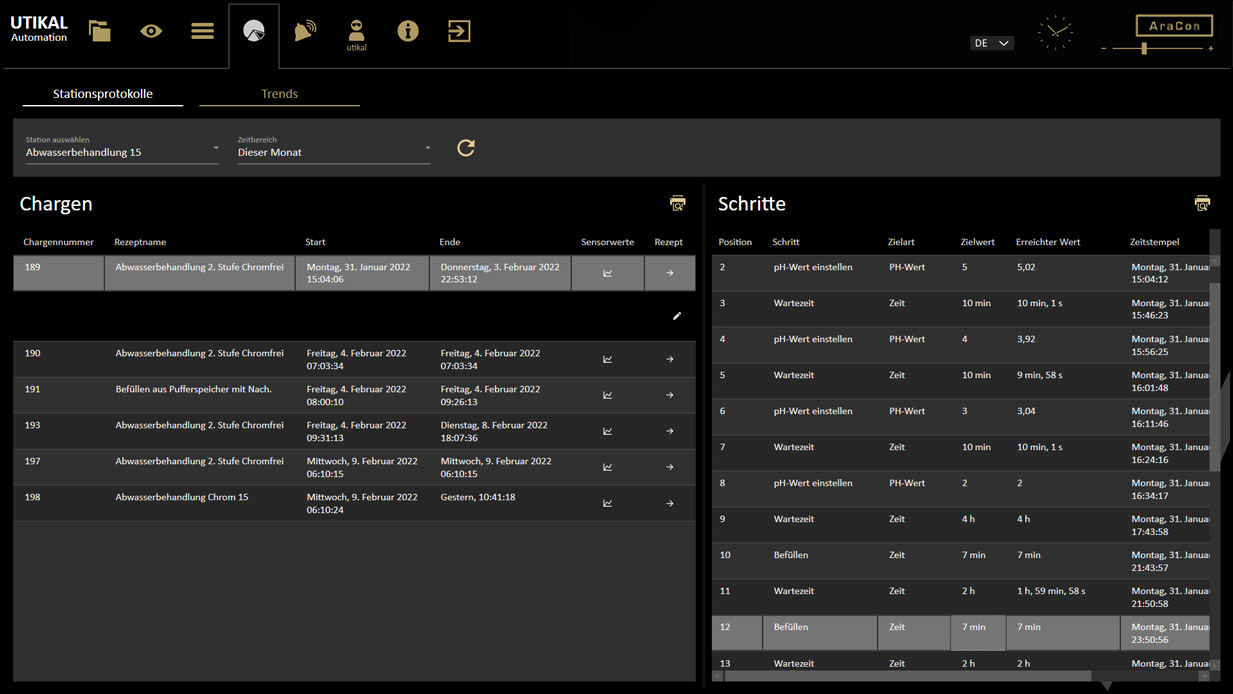

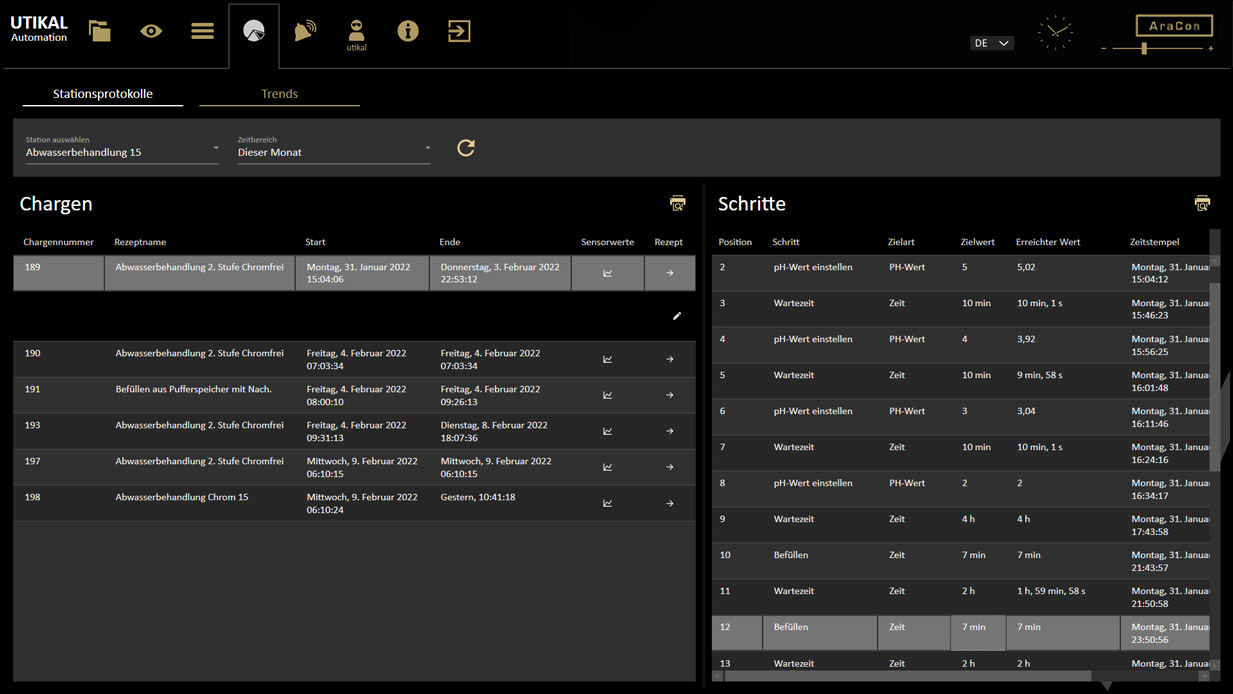

Our

optimized look

Our re-designed software does not only look good, but is also intuitive to use and learn.

FUNCTIONS

Every detail

in sight.

It is "up-to-date" in every aspect.

The operating concept is designed for fast and efficient work. Simple symbols are used for quick operation.

The standardized management of your data in an SQL server database ensures extended processes for your plant. Due to its programming in C# and .Net, subsequent wishes can be implemented quickly and cost-efficiently.

It is easy to handle.

By selecting the pumps, motors or valves, a selection menu is opened. Here you can choose between the settings Manual, Off and Automatic.

Automatic mode.

Your plant can be operated in automatic mode and manually. By pressing the automatic start button, your plant starts and works through the predefined steps, which usually include automatic filling of the treatment tank, neutralization, testing and draining of the batch.

Die Schritte können auch manuell angewählt werden. Die Automatik läuft anschließend weiter.

It reliably reports what your plant is doing.

All values for pH, conductivity, etc. are logged. The values can be viewed and printed out over any period of time. All batches and messages are logged with date and time.

More please!

Maintenance

Plug-in

The guard dog of your plant.

This module is for the maintenance of the equipment located in a surface coating or waste water plant. The baths and the tanks located in the plant are monitored and maintained.